BMW Werk Debrecen - Erweiterte statische Beratung

Fortschrittliche statische Prüfung und Optimierung für die Neuberechnung eines Kranbahnträgers

Strukturelle Highlights

- Neubewertung eines bestehenden Kranbahnträgers nach Lasterhöhung

- Mehrstufiger Verifizierungsprozess inklusive GZT- und GZG-Bewertungen

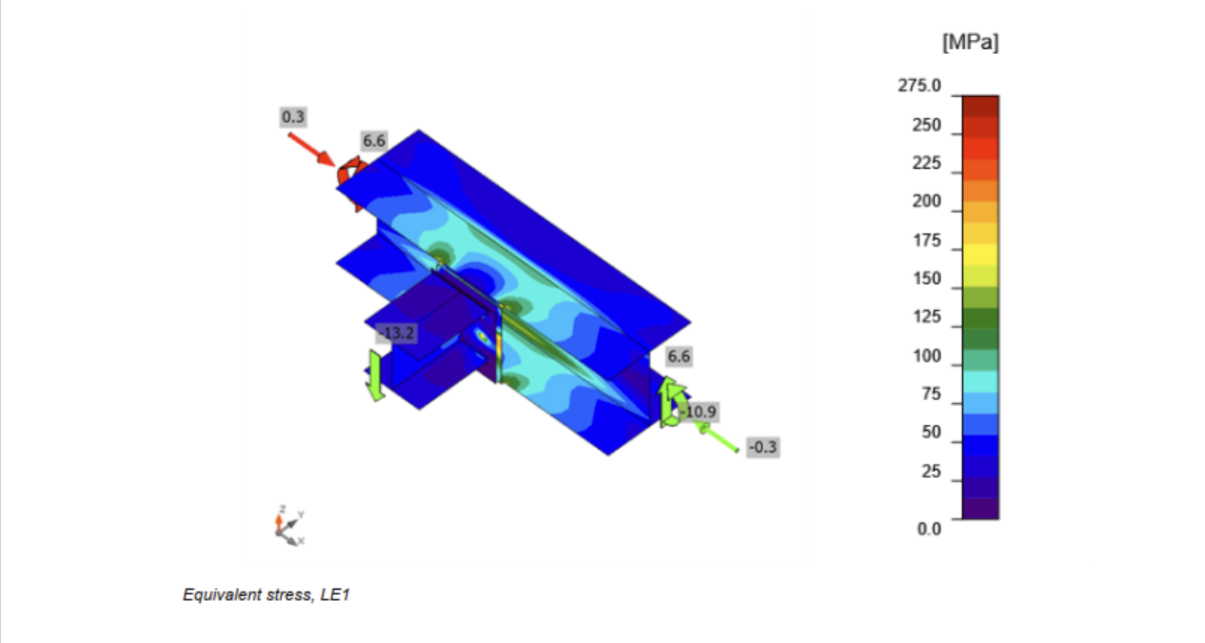

- Fortschrittliche Anschlussmodellierung mit IDEA StatiCa

- Kritische Bewertung von Stahl-Beton-Verankerungssystemen

- Erreichung von 97% Auslastung ohne bauliche Veränderungen

- Entwicklung und Test von KI-unterstützten Prüfwerkzeugen

Fakten

- Standort: Debrecen, Ungarn

- Jahr: 2025

- Leistungen: Tragwerksplanung

- Auftraggeber: Yapi Merkezi A.S

- Yapi Merkezi ist der größte türkische Auftragnehmer, der am türkischen Flughafen und am Bau der Canakkale-Brücke beteiligt ist

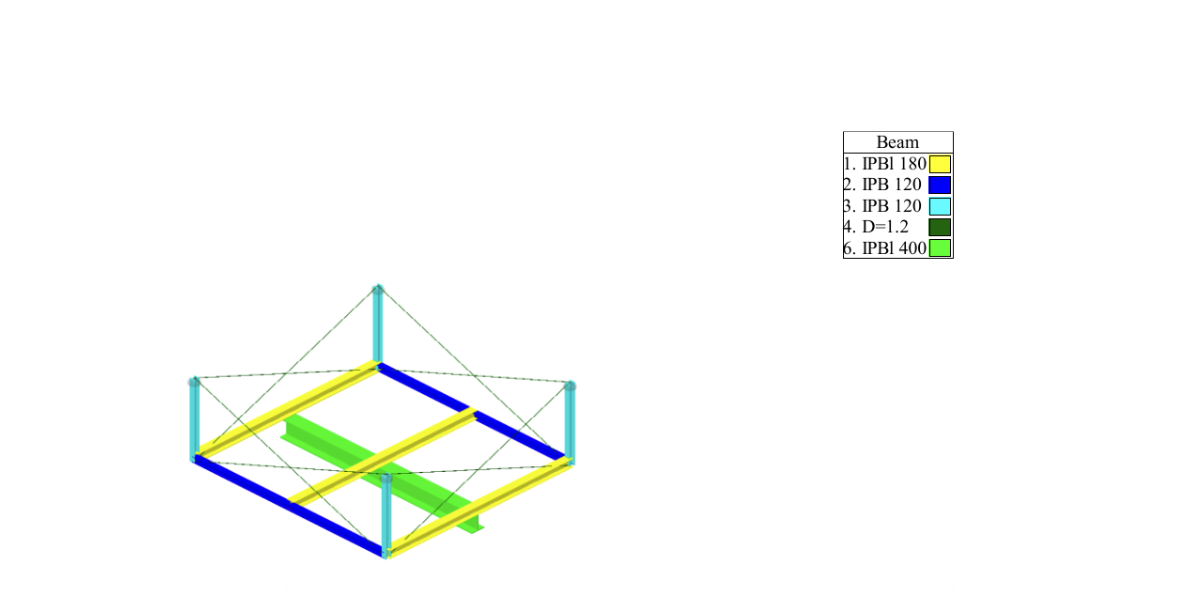

EHS Engineering & Consulting wurde von Yapi Merkezi beauftragt, während der Ausführung des BMW-Werks in Debrecen erweiterte tragwerksplanerische Beratung zu leisten. Unser Aufgabenbereich umfasste die unabhängige Überprüfung der Berechnungen des ungarischen Prüfingenieurs (EOR), die oft durch einen übermäßig konservativen Planungsansatz gekennzeichnet waren. Unser Ziel war es, sicherzustellen, dass diese Bewertungen technisch gerechtfertigt waren und nicht zu unnötigen Nachrüstungen oder Kostenerhöhungen führten. Eine Hauptaufgabe bestand in der Neubewertung eines Kranbahnträgers, der bereits konstruiert worden war. Nach der Installation verdoppelte der Kranhersteller (ABUS) die ursprünglich angenommenen Lasten, was zu deutlich erhöhten Reaktionskräften auf die Tragstruktur führte. EHS leitete eine vollständige Neuberechnung des Systems unter Anwendung eines mehrstufigen Prüfverfahrens. Wir führten eine Neubewertung im Grenzzustand der Tragfähigkeit (GZT) und Grenzzustand der Gebrauchstauglichkeit (GZG) unter Verwendung präziser Lastkombinationen durch. Die Verbindungen wurden mit IDEA StatiCa modelliert und bewertet, um eine fortschrittliche Bewertung von Anschlüssen und Steifigkeit zu ermöglichen. Das Verankerungssystem, das die Stahlkranbahn mit den Stahlbetonstützen verbindet, wurde kritisch untersucht. Anstatt auf kostspielige Nachrüstungsmaßnahmen zurückzugreifen, arbeiteten wir eng mit ABUS zusammen, um die tatsächlichen Lastmuster während des Betriebs zu ermitteln und diese mit den strukturellen Reserven des bestehenden Systems zu vergleichen. Das Ergebnis war eine finale Auslastung von bis zu 97%, ein anspruchsvoller, aber sicherer Konstruktionsrand, der ohne strukturelle Änderungen erreicht wurde. Angesichts der Komplexität und engen Toleranzen dieser Bewertung implementierten wir ein Vier-Augen-Prinzip. Zusätzlich testeten wir unser hausinternes KI-unterstütztes Werkzeug, das entwickelt wurde, um autonom angewandte Lasten zu überprüfen und strukturelle Berechnungen auf Fehler oder Inkonsistenzen zu überprüfen. Dies diente als zusätzliche Sicherheitsschicht und unterstrich unser Engagement für innovationsgetriebenes, präzises Engineering. Dieses Projekt demonstrierte die Stärke von EHS bei der Überbrückung von Design, Ausführung und Beratung, insbesondere in komplexen Schnittstellenbedingungen. Durch fortschrittliche Berechnungen, enge Zusammenarbeit mit Herstellern und den Einsatz modernster Werkzeuge lieferten wir sichere und effiziente Ingenieurslösungen, die Strukturen zu ihrer optimalen Leistung bringen und dabei alle anwendbaren Eurocode-Standards einhalten.