BMW Werk Debrecen - Bewertung der Tragwerksintegrität

Expertenkonsultation und statische Überprüfung für die Dachkonstruktionen des Pressenwerks und der Karosseriebauwerke

Strukturelle Highlights

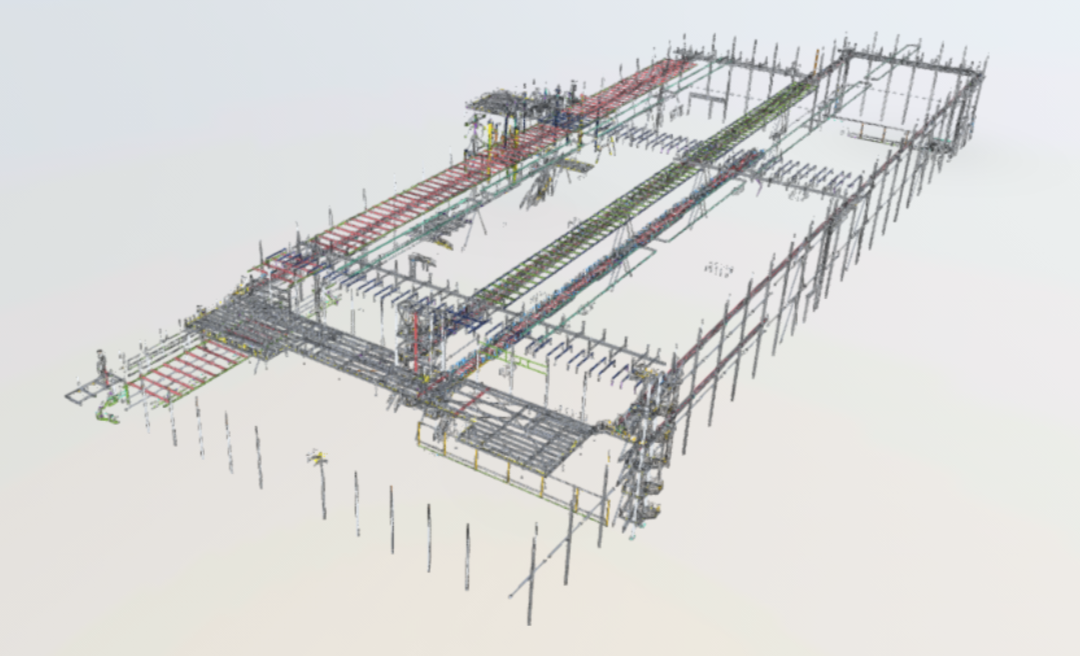

- Presswerk (TU): Die Konstruktion besteht aus starren Stahlrahmen, die auf Fertigteil-Stahlbetonstützen lagern, welche in Pfahlkopfbalken eingespannt und starr mit einer Stahlbetonplatte verbunden sind. Die Hochstützen wurden speziell für schwere Krane ausgelegt, die für den Transport der Pressen benötigt werden.

- Karosseriewerk (TKB): Das Dach ist als Stahlfachwerksystem auf einem 15 m x 15 m Raster konzipiert, getragen von Fertigteilstützen, die über Hülsen in die Pfahlkopfbalken eingespannt sind. Die Bodenplatte wurde als faserbewehrter Beton ausgeführt, um Schwinden und Rissbildung zu minimieren und eine klassische Bewehrung überflüssig zu machen.

Fakten

- Standort: Debrecen, Ungarn

- Auftraggeber: BMW Group

- Rolle: Expertenberatung und statische Überprüfung

- Umfang: Dachkonstruktionen des Pressenwerks (TU) und des Karosseriebauwerks (TKB)

- Leistungen: Unabhängige Überprüfung der Tragwerksberechnungen, technische Workshops

- Die neue BMW-Fabrik in Debrecen ist mit 4.000.000 m² doppelt so groß wie das Fürstentum Monaco.

EHS Engineering & Consulting wurde beauftragt, die Stahldachkonstruktionen des Presswerks (TU) und des Karosseriewerks (TKB) im neuen BMW-Werk in Debrecen auf ihre strukturelle Integrität zu prüfen. Während Bollinger + Grohmann das Haupttragwerkskonzept erarbeitete und der Generalunternehmer Yapi Merkezi die Detailplanung von Anschlüssen und Dachplattformen übernahm, führte EHS eine unabhängige Überprüfung der statischen Berechnungen durch und begleitete technische Workshops vor Ort, um dem Auftraggeber transparente und objektive Rückmeldungen zu geben. Das Presswerk besteht aus starren Stahlrahmen auf Fertigteilbetonstützen, die speziell für Schwerlastkrane ausgelegt wurden, während das Karosseriewerk über ein Stahlfachwerkdach in einem 15 m x 15 m Raster verfügt. Die Stützen sind über Hülsen in die Pfahlkopfbalken eingespannt, und die Bodenplatte wurde als faserbewehrter Beton ausgeführt, um Schwinden und Rissbildung zu minimieren und klassische Bewehrung zu vermeiden. Eine wesentliche Herausforderung lag in der Koordination zahlreicher Dokumente aus verschiedenen Planungsteams sowie in der Bewertung der vom Auftragnehmer vorgeschlagenen vielfältigen Anschlusslösungen. Durch detaillierte Analysen konnte nachgewiesen werden, dass viele Nachrüstungsforderungen des ungarischen Prüfingenieurs nicht erforderlich waren. Dies gelang durch die Anwendung von Lastkombinationen anstelle von Ergebniskombinationen, die Berücksichtigung lokaler Singularitäten, plastische Bemessung und die konsequente Einhaltung des Eurocodes. So wird mit modernen Analysewerkzeugen jede Tragfähigkeitsreserve ausgeschöpft, um Sicherheit und Effizienz ohne unnötigen Konservatismus zu gewährleisten.